We will use trenchless construction techniques, where appropriate, to minimize disruptions. This may be used where the pipeline crosses roads and railways, for select watercourse crossings, and places with restricted workspace such as in some urban areas. Multiple trenchless construction techniques are employed with the selected methodology based on geotechnical conditions, available working space, and length of the trenchless crossing.

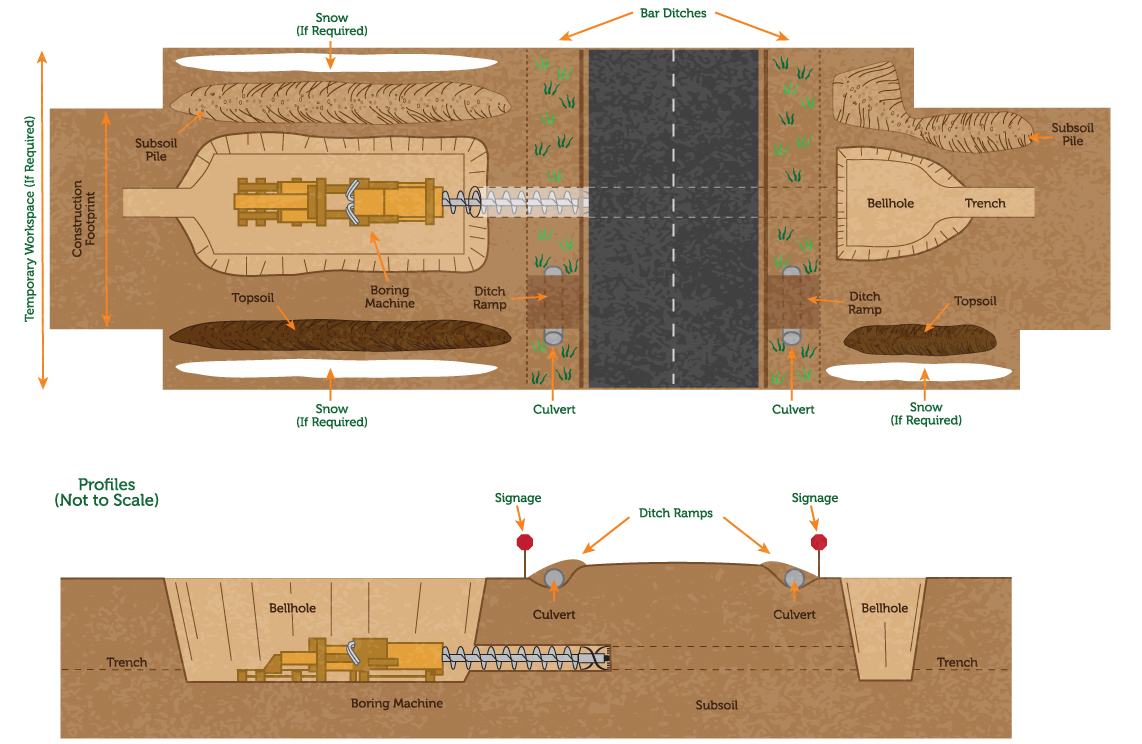

Road or Rail Boring - This technique involves digging a hole where a boring machine can sit level with the depth where the pipe will be installed under the road or railway. The boring machine is then used to bore under the road or railway. Finally, the length of assembled pipe is threaded through the hole. Conventional pipeline construction will take place on either side of the road or railway crossing.

Horizontal Direction Drilling (HDD) – This technique involves set-up of an HDD drill rig on one side of the crossing with a series of drills and reams along the drill path. The pipe is assembled and welded on the opposite side to the drill set-up, with the pipe string connected to the drill assembly and pulled back through the drill path.

Direct Pipe (DP) – This technique involves set-up of a drill rig on one side of the crossing with the drill head advancing the drill path and the pipe sequentially welded and inserted as the drill head advances.